ACCREDITATIONS / APPROVALS

認証一覧

ACCREDITATIONS/APPROVALS

認証一覧

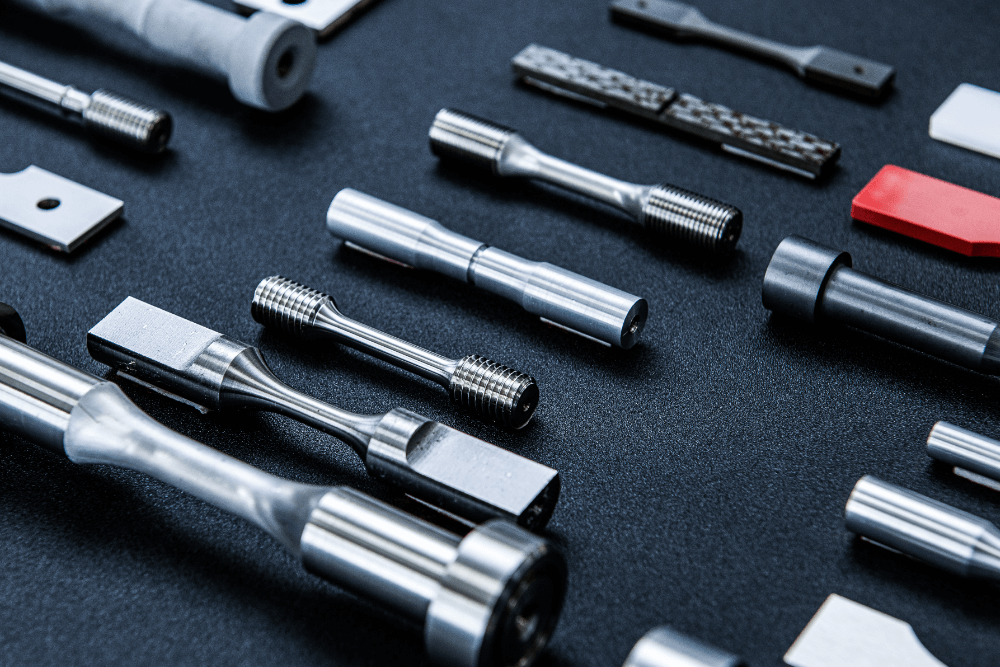

当社は、ISO 9001とISO/IEC 17025を基盤とした管理方法を導入し、原子力産業や航空機産業など幅広い分野の要求事項に応えています。また、国内で初めて材料試験分野のNadcap(航空宇宙業界における特殊工程の国際認定プログラム)を取得した実績があります。品質マネジメントシステムは、お客様の要求に応える上で最重要事項であると考えております。

顧客の要求に応える上で、品質マネジメントシステムは最も重要なものと捉え、今後も品質保証を核とした試験・加工・設計・分析サービスを提供し、国内外の顧客の期待にお応えします。

JIS Q 9001・JIS Q 9100

株式会社神戸工業試験場は、従来よりISO 9001:2000(品質マネジメントシステム)を取得し、試験場として信頼を得てきましたが、2005年により信頼性の高い航空宇宙産業向けの品質マネジメントシステム規格JIS Q 9100の認証を受けました。

JIS Q 9100とは、ISO 9001に航空・宇宙・防衛産業界固有の要求事項を加えて設定された規格です。同等の規格として、米国ではAS9100、欧州ではEN9100として制定されています。JIS Q 9100は、航空・宇宙・防衛産業に関わる企業を対象とした品質マネジメントシステムの規格となります。

| 認定・登録機関 | (一財)日本品質保証機構(JQA) |

|---|---|

| 登録証番号 | JQA-QMA16298(ISO 9001) JQA-QMA12316(ISO 9001) JQA-AS0019(JIS Q9100) |

.png)

.png)

.png)

JIS Q 17025(ISO/IEC 17025)【機械・物理試験、化学試験】

ISO/IEC 17025とは、国際標準化機構によって策定された試験所及び校正機関の能力に関する一般要求事項の国際標準規格です。試験所認定は、信頼性のある試験所として試験及び校正業務を提供できる証となります。日本適合性認定協会が認定した試験所の試験報告書は、相互認証に基づき世界に通用します。

当社はこの認定を1998年に取得し、現在では下記範囲で認定を受けています。

| 認定・登録機関 | (公財)日本適合性認定協会(JAB) |

|---|---|

| 登録証番号 | RTL00430 |

播磨事業所で認定を受けている範囲及び認定規格概要

M25

機械・物理試験

| – |

|---|

M25.A1.1

鉄鋼・非鉄金属

| – |

|---|

B13.1

引張・伸び試験

| JIS Z 2241 |

|---|

| ASTM E8/E8M |

| ISO 6892-1 |

| JIS G 0567、ISO 6892-2 |

| ASTM E21、EN 10002-5:1991 |

| ISO 6892-3 |

| ISO 5178 |

| JIS Z 3121、ISO 4136、EN 895:1995 |

| ASTM B557/B557M |

B13.3.1

曲げ試験

| JIS Z 2248、ISO 7438 |

|---|

| JIS Z 3122、ISO 5173 |

| EN 910:1996 |

B13.4.1

シャルピー衝撃試験

| JIS Z 2242、ISO 148-1、EN 10045-1:1990 |

|---|

| ASTM E23 |

B13.6.1

ブリネル硬さ試験

| JIS Z 2243-1、JIS Z 2243-2、ASTM E10 |

|---|

B13.6.2

ビッカース硬さ試験

| JIS Z 2244-1、JIS Z 2244-2、ISO 6507-1、ISO 6507-4 |

|---|

| ASTM E384(ヌープ硬さを除く) |

| ASTM E92(ヌープ硬さを除く) |

B13.6.3

ロックウェル硬さ試験

| JIS Z 2245 |

|---|

| ASTM E18 |

B13.5.1

破壊じん性試験

| JIS G 0564:1999、ASTM E399 |

|---|

| ASTM E1820、E1921 |

B13.5.2

落重試験

| ASTM E208 |

|---|

B13.15.1

高サイクル疲労試験

| ASTM E466 |

|---|

B13.15.2

低サイクル疲労試験

| JIS Z 2279 |

|---|

| ASTM E606/606M |

B13.15.6

亀裂成長試験

| ISO 12108 |

|---|

| ASTM E647 |

B13.16.1

引張クリープ試験

| JIS Z 2271、ASTM E139、ASTM E292 |

|---|

B2.1

組織試験

| ASTM E3 |

|---|

B2.1.1

マクロ組織試験

| JIS G 0553、ASTM E340 |

|---|

| ISO 17639、EN 1321:1996 |

B2.1.2

ミクロ組織試験

| ASTM E407、EN 1321:1996 |

|---|

| ISO 17639 |

B2.1.3

結晶粒度試験

| JIS G 0551、NF EN ISO 643(試験片の調整:熱処理工程を除く)(評価方法:計数方法を除く) |

|---|

| ASTM E112(試験片の調整:熱処理工程を除く)(評価方法:求積法を除く) |

| ASTM E930 |

B2.1.4

非金属介在物の 顕微鏡試験

| JIS G 0555 |

|---|

| ASTM E45(方法A、方法D) |

M25.A1.2

締結用部品

| – |

|---|

B2.2.2

脱炭層深さ測定試験

| JIS B 1051 (9.10.2)顕微鏡による方法 |

|---|

M25.A2.1

プラスチック

| – |

|---|

B13.1

引張・伸び試験

| JIS K 7161-1、JIS K 7161-2(ポアソン比測定を除く) |

|---|

B13.3.1

曲げ試験

| JIS K 7171 |

|---|

B13.4.1

シャルピー衝撃試験

| JIS K 7111-1 |

|---|

B13.4.2

アイゾット衝撃試験

| JIS K 7110 |

|---|

B13.6.3

ロックウェル硬さ試験

| JIS K 7202-2 |

|---|

M25.A13

複合材料

| – |

|---|

B13.1

引張・伸び試験

| ASTM D3039/D3039M (ポアソン比、遷移ひずみ測定は除く) |

|---|

B13.2.1

一軸圧縮試験

| SACMA SRM1R |

|---|

| ASTM D6641/D6641M (ポアソン比測定は除く) |

B13.8.2

せん断試験

| ASTM D2344/D2344M |

|---|

| ASTM D3518/D3518M |

M26

化学試験

| – |

|---|

M26.A1/B1.2

金属:鉄鋼

容量分析Ⅰ:錯滴定

| JIS G 1216-2 |

|---|

M26.A1/B1.2

金属:鉄鋼

容量分析Ⅰ:酸化還元滴定

| JIS G 1217 4. a) |

|---|

M26.A1/B2.1

金属:鉄鋼

吸光光度分析:赤外分光分析

| JIS G 1211-3 [8.2 a),c)を除く] |

|---|

| JIS G 1215-4(10.1, 10.2を除く) |

M26.A1/B2.1

金属:鉄鋼

吸光光度分析:紫外・可視分光分析

| JIS G 1213 4. b)、JIS G 1214 4. a) |

|---|

| JIS G 1212-2 |

M26.A1/B2.4

金属:鉄鋼

発光分光分析:ICP-AES

| JIS G 1258-1、JIS G 1258-2*一部変更(Nbの定量範囲の上限を拡大) |

|---|

| JIS G 1258-3*一部変更(定量範囲の上限を拡大) |

| JIS G 1258-5 |

M26.A1/B4.3

金属:鉄鋼

熱伝導度測定:熱伝導度法

| JIS G 1228-3*一部変更(対象品種の変更及び及び定量範囲の上限を拡大) |

|---|

M26.A1/B1.2

金属:ニッケル合金

容量分析Ⅰ:錯滴定

| JIS G 1216-2 *一部変更(対象品種及び定量範囲を変更) |

|---|

M26.A1/B1.2

金属:ニッケル合金

容量分析Ⅰ:酸化還元滴定

| JIS H 1279 4. b)*一部変更(定量範囲の上限を拡大) |

|---|

M26.A1/B2.1

金属:ニッケル合金

吸光光度分析:赤外分光分析

| JIS H 1275 4. e)、JIS H 1277 4. d) |

|---|

M26.A1/B2.1

金属:ニッケル合金

吸光光度分析:紫外・可視分光分析

| JIS H 1276 4. b)、JIS H 1278 4. a) |

|---|

M26.A1/B2.4

金属:ニッケル合金

発光分光分析:ICP-AES

| JIS H 1289*一部変更(測定成分を拡大) |

|---|

M26.A1/B4.3

金属:ニッケル合金

熱伝導度測定:熱伝導度法

| JIS G 1228-3*一部変更(対象品種の変更及び及び定量範囲の上限を拡大) |

|---|

茨城事業所で認定を受けている範囲及び認定規格概要

M25

機械・物理試験

| – |

|---|

M25.A1.1

鉄鋼・非鉄金属

| – |

|---|

B13.1

引張・伸び試験

| JIS Z 2241、ASTM E8/E8M |

|---|

| JIS G 0567 |

| ASTM E21 |

| JIS Z 3121 |

| ASTM B557/B557M |

| ISO 6892-1 |

| ISO 6892-2 |

B13.3.1

曲げ試験

| JIS Z 3122 |

|---|

B13.4.1

シャルピー衝撃試験

| JIS Z 2242, ISO 148-1 |

|---|

B13.6.1

ブリネル硬さ試験

| JIS Z 2243-1、JIS Z 2243-2、ASTM E10 |

|---|

B13.6.2

ビッカース硬さ試験

| JIS Z 2244-1、JIS Z 2244-2、ASTM E92(ヌープ硬さを除く) |

|---|

B13.6.3

ロックウェル硬さ試験

| JIS Z 2245 |

|---|

| ASTM E18 |

B13.5.1

破壊じん性試験

| ASTM E399 |

|---|

| ASTM E1820、ASTM E1921 |

B2.1

組織試験

| ASTM E3 |

|---|

B2.1.1

マクロ組織試験

| JIS G 0553、ASTM E340 |

|---|

| ISO 17639、EN 1321:1996 |

B2.1.2

ミクロ組織試験

| ASTM E407、EN 1321:1996 |

|---|

| ISO 17639 |

B2.1.3

結晶粒度試験

| JIS G 0551、NF EN ISO 643(試験片の調整:熱処理工程を除く)(評価方法:計数方法を除く) |

|---|

| ASTM E112(試験片の調整:熱処理工程を除く)(評価方法:求積法を除く) |

B2.1.4

非金属介在物の 顕微鏡試験

| JIS G 0555 |

|---|

| ASTM E45(方法A、方法D) |

M25.A1.2

締結用部品

| – |

|---|

B2.2.2

脱炭層深さ測定試験

| JIS B 1051 (9.10.2)顕微鏡による方法 |

|---|

なお詳細は、(公財)日本適合性認定協会(JAB)のホームページをご覧下さい。

JIS Q 17025は、試験所の能力認定規格のことで、個別の試験項目に対し、試験を実施する能力があることを認定するものです。 Nadcap(米国航空宇宙産業・防衛産業契約者認証プログラム)における材料試験所は、JIS Q 17025の認証取得が義務付けられています。

JIS Q 17025(ISO/IEC 17025)【校正機関認定】

「JIS Q 17025校正機関」における試験機の試験力校正分野で、公益財団法人日本適合性認定協会から認定を受けています。

認定対象

– ねじ式一軸試験機

– 疲労試験機(一軸油圧式サーボ式)

– クリープ・ラプチャー試験機(レバー式)

| 認定・登録機関 | (公財)日本適合性認定協会(JAB) |

|---|---|

| 登録証番号 | RCL00490 |

| 校正範囲 | 拡張 不確かさ |

常用参照 標準器 |

|---|

M14.6

力

| – |

|---|

M14.6.1

一軸試験機(試験力)

引張・圧縮一軸試験機(引張のみ)

| 1 kN 以上 100 kN 以下 |

0.27% | 1級 (JIS/ISO) |

|---|

M14.6.1

一軸試験機(試験力)

引張・圧縮一軸試験機(引張のみ)

| 1 kN 以上 100 kN 以下 |

0.41% | Class A (ASTM) |

|---|

M14.6.1

一軸試験機(試験力)

レバ一式引張一軸試験機

| 0.5 kN 以上 30 kN 以下 |

0.21% | 1級 (ISO) |

|---|

M14.6.1

一軸試験機(試験力)

レバ一式引張一軸試験機

| 0.5 kN 以上 30 kN 以下 |

0.24% | Class A (ASTM) |

|---|

JIS Q 17043(ISO/IEC 17043)【機械・物理試験、化学試験】

JIS Q 17043とは、ISO/IEC 17043を基に技術的内容及び構成を変更することなく作成した日本工業規格であり、認定機関が要求事項を満たした技能試験提供者に対し、認定を与えるものです。

技能試験提供者の認定は、特定の種類の技能試験を提供する技能試験提供者の能力を決定する手段の一つです。能力ある技能試験提供者の正式な承認であることから、顧客ニーズを満足する信頼性のある技能試験提供者を識別し、選定するための簡便な手段を顧客に提供するものでもあります。

神戸工業試験場のグループ会社であるKMTLエッジテックでは、この認定を2016年2月に取得、2018年2月6日に第2回目の認定の拡大を行い、下記の技能試験を実施できるようになりました。

| 認定・登録機関 | (公財)日本適合性認定協会(JAB) |

|---|---|

| 登録証番号 | PTP00040 |

M25

機械・物理試験

| – |

|---|

M25.1

金属材料・締結用部品

| – |

|---|

M25.1.1

鉄鋼・非鉄金属

| 対象試験は附属書(1/3頁)参照 |

|---|

M25.1.2

締結用部品

| 対象試験は附属書(1/3頁)参照 |

|---|

M26

化学試験

| – |

|---|

M26.1

金属、原材料、関連製品

| 対象元素及び規格は附属書(2/3頁)参照 |

|---|

M26.17

水

| – |

|---|

M26.17.1

排水、環境水

| 対象元素及び規格は附属書(3/3頁)参照 |

|---|

なお詳細は、(公財)日本適合性認定協会(JAB)のホームページをご覧下さい。

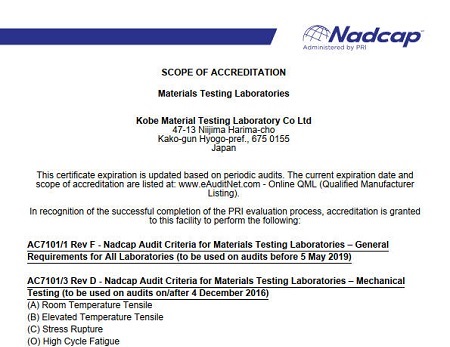

Nadcap

Nadcapとは、航空宇宙・防衛産業界の特殊工程*の国際認証制度であり、米国のNPOであるPRIが審査機関として運営しています。PRIには、世界の航空宇宙関連プライムメーカー(ボーイング、エアバス、GE、ロールスロイス等)が参加しています。プライムメーカー各社がサプライヤーにNadcap認証取得を義務付けています。

*特殊工程とは、プロセスの結果として得られる製品が、容易に又は経済的に検査できない工程のこと。

| 播磨事業所認定項目(〒675-0155 兵庫県加古郡播磨町新島47-13) |

|---|

| 登録審査団体 PRI(Performance Review Institute) |

Materials Testing

当社は従来よりISO 17025認定を取得し、第三者機関の試験場として信頼を得てきましたが、2006年7月13日に日本で初めてNadcap認証を受けた材料試験所(MTL)となりました。以降更新と範囲の拡大を受けております。

■試験コード

■試験項目

| ■主な適用規格 |

|---|

A

常温引張試験

| ASTM E8/E8M |

|---|

B

高温引張試験

| ASTM E21 |

|---|

C

ラプチャー試験

| ASTM E139 |

|---|

XA

クリープ試験

| ASTM E139 |

|---|

P

破壊靭性試験

| ASTM E399 |

|---|

O

高サイクル疲労試験

| ASTM E466 |

|---|

Y

低サイクル疲労試験

| ASTM E606 |

|---|

XE

き裂伝播試験

| ASTM E647 |

|---|

L0

金属組織

| ASTM E3、 ASTM E340 |

|---|

L1

微小圧痕硬さ

| ASTM E384 |

|---|

L11

結晶粒度測定

| ASTM E112 |

|---|

L12

介在物測定

| ASTM E45 |

|---|

L7

表面近傍の評価―IGA,IGO

| ASTM E3 |

|---|

XL

断面のマクロ評価

| ASTM E340 |

|---|

M1

ブリネル硬さ

| ASTM E10 |

|---|

M2

ロックウェル硬さ

| ASTM E18 |

|---|

M3

ビッカース硬さ

| ASTM E92 |

|---|

Z

標準試験片加工

| AC 7101/7 |

|---|

Z1

低応力研削

| AC 7101/7 |

|---|

Z2

低応力研削及び研磨

| AC 7101/7 |

|---|

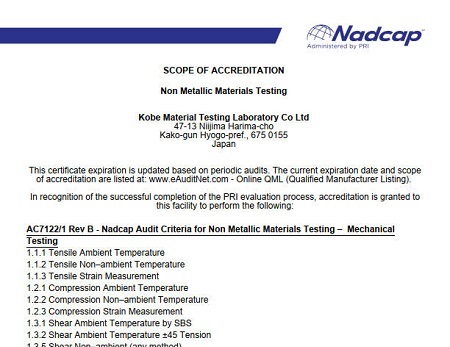

Non Metallic Materials Testing

当社は、2017年8月に日本で初めてNadcapの非金属材料試験(NMMT)機械試験の認証を取得した試験所です。

Class A : Composites

■試験コード

■試験項目

| ■主な適用規格 |

|---|

1.1.1

引張試験(常温)

| ASTM D3039/D3039M、 ASTM D5766/5766M |

|---|

1.1.2

引張試験(非常温)

| ASTM D3039/D3039M、 ASTM D5766/5766M |

|---|

1.1.3

引張試験(ひずみ測定)

| ASTM D3039/D3039M |

|---|

1.2.1

圧縮試験(常温)

| ASTM D6641/D6641M、 SACMA SRM1、 ASTMD6484/D6484M |

|---|

1.2.2

圧縮試験(非常温)

| ASTM D6641/D6641M、 SACMA SRM1、 ASTMD6484/D6484M |

|---|

1.2.3

圧縮試験(ひずみ測定)

| ASTM D6641/D6641M、 SACMA SRM1 |

|---|

1.3.1

せん断試験(SBS)

| ASTM D2344/D2344M |

|---|

1.3.2

せん断試験(±45Tension)

| ASTM D3518/D3518M |

|---|

1.3.4

せん断試験(V Notch)

| ASTM D5379/D5379M |

|---|

1.3.5

せん断試験(非常温)

| ASTM D2344/D2344M、 ASTM D3518/D3518M |

|---|

1.3.6

せん断試験(ひずみ測定)

| ASTM D3518/D3518M |

|---|

1.18.1

G1c

| ASTM D5528 |

|---|

2.2.1

密度/比重

| ASTM D792 |

|---|

F.2.1

試験片作成

| AC7122-I |

|---|

F.3.1

試験片加工

| AC7122-I |

|---|

GE Aviation 【特殊工程】-認定規格 S-400

GE S-400とは、米国GE Aviationの材料試験所に関する認定規格です。当社は、GEの審査に合格し、S-400ラボとして認定を受けています。認定範囲は下記の通りです。

| サプライヤーコード | T4274 |

|---|

■S-400 code

| ■試験項目 |

|---|

AI0A

| 常温引張試験 |

|---|

AI0B

| 高温引張試験 |

|---|

AI0C

| ラプチャー試験 |

|---|

AI0L

| ミクロ試験及び微小硬さ |

|---|

AI1M

| ブリネル硬さ |

|---|

AI2M

| ロックウェル硬さ |

|---|

AI3M

| ビッカース硬さ |

|---|

AI0N

| 衝撃試験 |

|---|

AI0O

| HCF試験 |

|---|

AI0P

| 破壊靱性試験 |

|---|

AI0Y

| LCF試験 |

|---|

AI0Z

| 低応力研削及び研磨 P1TF79 |

|---|

AIXA

| クリープ試験 |

|---|

AIXE

| 亀裂伝播試験 |

|---|

AIXL

| マクロ金属組織 |

|---|

AIXR

| 余寿命評価 |

|---|

AIXZ

| E50TF133結晶粒度評価試験 |

|---|

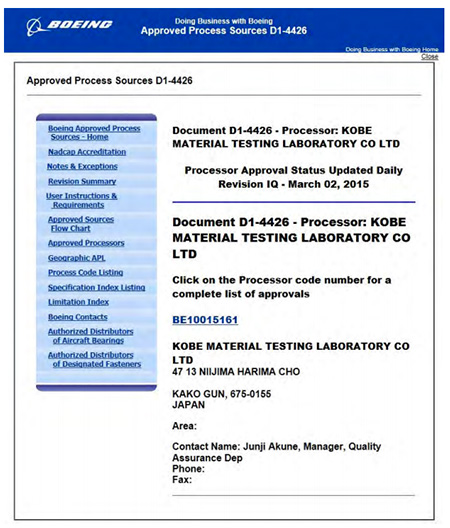

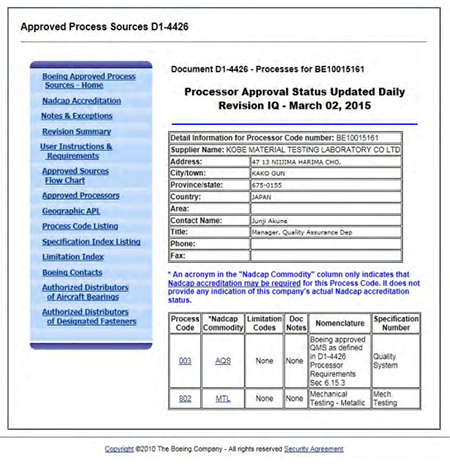

ボーイング社のD1-4426認定事業者(MTL)の承認について

D1-4426とは、ボーイング社のサプライヤーに対する要求事項です。当社は、D1-4426の要求に基づいたボーイング社の審査に合格し、ボーイング社のサプライヤーとして材料試験で認定を受けています。

| 認定の種類 | D1-4426 |

|---|---|

| 認定の対象 | 金属材料 機械試験 |

| プロセッサーコード | BE10015161 |

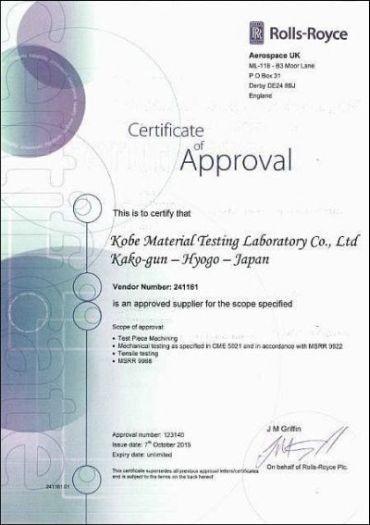

Rolls-Royce社の認定について

当社は、Rolls-Royce社の審査に合格し、Rolls-RoyceのSupplier(供給会社)として認定を受けています。

| ベンダーナンバー | 241161 |

|---|---|

| 試験項目 | ・試験片機械加工 ・機械試験(MSRR9922) |

■分類

| ■加工・試験品目 |

|---|

試験片加工

| 試験片加工 |

|---|

| 低応力研磨 |

機械試験

| 常温引張試験 |

|---|

| 高温引張試験 |

| ストレスラプチャー試験 |

| クリープ試験 |

| 破壊じん性試験 |

| き裂伝播試験 |

| 低サイクル疲労試験 |

硬さ試験

| ブリネル硬さ試験 |

|---|

| ロックウェル硬さ試験 |

| ビッカース硬さ試験 |

組織試験

| 表面近傍の評価 – IGA, IGO |

|---|

| マクロ組織試験 |

| 金属組織の評価 |

| 微小硬さ試験 |

| 結晶粒度評価 |

| 介在物測定 |

Pratt & Whitney 認定

当社は米国Pratt & Whitneyの審査に合格し、材料試験所としての認定を受けています。認定の範囲は下記の通りです。

■Test code

| ■試験項目 |

|---|

1

| 常温引張試験 |

|---|

3

| ストレスラプチャー試験 |

|---|

7-a

| 結晶粒度測定 |

|---|

7-d

| ミクロ組織試験(ロウ付け、タック溶接) |

|---|

7-e

| ミクロ組織試験(溶接) |

|---|

7-f

| ミクロ組織試験(レーザー加工) |

|---|

7-h

| ミクロ組織試験(熱処理) |

|---|

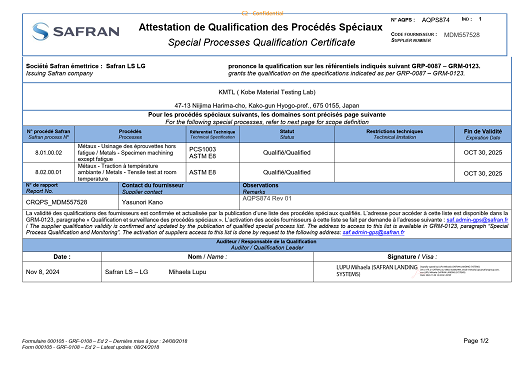

Safran Landing Systems社の認定について

当社はSafran Landing Systems社の審査に合格し、材料試験所としての認定を受けています。認定の範囲は下記の通りです。

| 認定の種類 | Special Processes Qualification |

|---|---|

| 認定の対象 | ・試験片加工(疲労試験を除く) ※適用図面はPCS1003, 100028952, 100028954, 100028955に限る。 ・室温引張試験(ASTM E8適用) |

| サプライヤ番号 | MDM557528 |

株式会社IHI

| 認定の種類 | ISAJT-F002, J-ISAJT-F002 |

|---|---|

| 認定の対象 | 非金属材料 材料試験 |

機械試験

■試験コード *1

■試験項目

| ■主な適用規格 |

|---|

A(R,E,C)

引張試験(室温,高温,低温)

| ASTM D3039/D3039M |

|---|

B(R,E,C)

面内せん断試験(室温,高温,低温)

| ASTM D3518/D3518M |

|---|

C(R,E,C)

圧縮試験(室温,高温,低温)

| SACMA SRM1 |

|---|

D(R,E,C)

圧縮試験(室温,高温,低温)

| ASTM D6641/D6641M |

|---|

E(R,E,C)

ショートビームせん断強度試験(室温,高温,低温)

| ASTM D2344/D2344M |

|---|

N(R,E,C)

曲がり梁試験(室温,高温,低温)

| ASTM D6415/D6415M |

|---|

*1 コード中の(R,E,C)はそれぞれ試験条件の室温(R)、高温(E)、低温(C)を示す。

物理/化学/熱物性/分析 試験

■試験コード

■試験項目

| ■主な適用規格 |

|---|

2A

複合材強化材の含有率

| ASTM D3171 |

|---|

2B

密度および比重

| ASTM D792 |

|---|

| ASTM D1505 |

| ASTM D297 |

試験片加工

■試験コード

■試験項目

| ■主な適用規格 |

|---|

3B

PMC 試験片加工(タブ接着なし)

| ISAJT-F004 Class-B |

|---|

| 認定の種類 | ISAJT-F005, J-ISAJT-F005 |

|---|---|

| 認定の対象 | 金属材料 材料試験 |

播磨事業所

■試験コード

■試験項目

| ■主な適用規格 |

|---|

A

常温引張試験

| ASTM E8/E8M and/or B557 |

|---|

B

高温引張試験

| ASTM E21 |

|---|

C

ストレスラプチャー試験

| ASTM E21(平滑材) |

|---|

| and/or E292 (切欠き材) |

XA

クリープ試験

| ASTM E139 |

|---|

O

荷重制御疲労試験

| ASTM E466 |

|---|

Y

歪制御疲労試験

| ASTM E606 |

|---|

P

破壊靭性試験

| ASTM E399 |

|---|

XE

亀裂伝播試験

| ASTM E647 |

|---|

L

金属組織試験

| ASTM E3 and/or E407 and/or E340 |

|---|

La

結晶粒度

| ASTM E112 nd/or E930 and/or E1181 |

|---|

L1

ミクロ硬さ内部

| ASTM E384 |

|---|

M1

ブリネル

| ASTM E10 |

|---|

M2

ロックウェル/スーパーフィシャル

| ASTM E18 |

|---|

M3

ビッカース

| ASTM E92 |

|---|

Z

低応力試験片加工

| ISAJT-F001 |

|---|

茨城事業所

■試験コード

■試験項目

| ■主な適用規格 |

|---|

A

常温引張試験

| ASTM E8/E8M and/or B557 |

|---|

B

高温引張試験

| ASTM E21 |

|---|

O

荷重制御疲労試験

| ASTM E466 |

|---|

Y

歪制御疲労試験

| ASTM E606 |

|---|

XE

亀裂伝播試験

| ASTM E647 |

|---|

Z

低応力試験片加工

| ISAJT-F001 |

|---|

| 認定の種類 | ISAJT-F009 |

|---|---|

| 認定の対象 | CMCおよびCMC素材の材料試験 |

■試験コード

■試験項目

| ■主な適用規格 |

|---|

1J

引張疲労試験

| ASTM C1360 |

|---|

三菱重工業株式会社 民間機セグメント

| 認定の種類 | MSJ4000 |

|---|---|

| 適用基本要求 | AS/EN/JIS Q 9100:2016 |

| 適用範囲 | 航空宇宙産業用材料、部品、製品における試験片製作、試験、調査及び報告書の作成 |

| 適用除外項目 | 8.3 製品及びサービスの設計・開発 |

三菱重工業株式会社 航空宇宙事業本部

| 認定の種類 | MS84001 セクションB |

|---|---|

| 適用範囲 | 製造 |

| 適用製品 | 試験片の作成、引張試験の委託加工外注のみ |

| 限定条件 | SM-3 ノーズコーンシュラウドの引張試験に限る |

川崎重工業株式会社 航空宇宙システムカンパニー

| 認定の種類 | KQ-7204 |

|---|---|

| 認定の対象 | 材料試験 |

播磨事業所

■試験コード

■試験項目

| ■主な適用規格 |

|---|

1

常温引張

| ASTM E8、ASTM B557、JIS Z2241 |

|---|

2

高温引張

| ASTM E21、JIS G0567 |

|---|

3

ストレスラプチャー

| ASTM E139、ASTM E292、JIS Z2271 |

|---|

4

クリープ試験

| ASTM E139、JIS Z2271 |

|---|

5

疲労(荷重制御)

| ASTM E466 |

|---|

6

疲労(歪制御)

| ASTM E606 |

|---|

7

疲労亀裂進展

| ASTM E647、ISO 12108 |

|---|

9

衝撃試験

| ASTM E23、 JIS Z2242 |

|---|

11

曲げ試験

| ISO 7438、JIS Z2248 |

|---|

20

ブリネル

| ASTM E10、JIS Z2243 |

|---|

21

ロックウェル

| ASTM E18、JIS Z2245 |

|---|

22

ビッカース

| ASTM E92、JIS Z2244 |

|---|

23

微小硬さ

| ASTM E92、ASTM E384 |

|---|

30

ミクロ組織一般

| ASTM E3、ASTM407 |

|---|

30-a

結晶粒度

| ASTM E112、ASTM E930 |

|---|

30-e

機械加工

| ― |

|---|

30-f

特殊加工

| ― |

|---|

31

マクロ組織

| ASTM E340 |

|---|

71

試験片加工

| ― |

|---|

72

低応力試験片加工

| ― |

|---|

200

密度

| JIS Z 8807 |

|---|

201

比熱

| ASTM E1269 |

|---|

202

熱膨張

| ASTM E1461 |

|---|

203

熱拡散

| ASTM E1461 |

|---|

204

熱膨張

| ASTM E228、ASTM E831 |

|---|

210

弾性率

| ASTM E1875 |

|---|

Wege crack Propagation (JAEC-J-MCL-S-100)

| 認定の種類 | J-ISAJT-F002 |

|---|---|

| 認定の対象 | 非金属材料 材料試験 |

| 認定の種類 | J-ISAJT-F005 |

|---|---|

| 認定の対象 | 金属材料 材料試験 |

播磨事業所

■コード

■試験項目

| ■主な適用規格 |

|---|

A

常温引張試験

| ASTM E8/E8M、ASTM B557 |

|---|

B

高温引張試験

| ASTM E21 |

|---|

C

ストレスラプチャー試験

| ASTM E139 (平滑材) |

|---|

| ASTM E292 (切欠き材) |

XA

クリープ試験

| ASTM E139 |

|---|

O

荷重制御疲労試験

| ASTM E466 |

|---|

Y

歪制御疲労試験

| ASTM E606 |

|---|

P

破壊靭性試験

| ASTM E399 |

|---|

XE

亀裂伝播試験

| ASTM E647 |

|---|

L

金属組織試験

| ASTM E3、ASTM E407、ASTM E340 |

|---|

La

結晶粒度

| ASTM E112、ASTM E930、ASTM E1181 |

|---|

L10

機械加工

| *1 |

|---|

L13

その他

| *1 |

|---|

M1

ブリネル

| ASTM E10 |

|---|

M2

ロックウェル/スーパーフィシャル

| ASTM E18 |

|---|

M3

ビッカース

| ASTM E92 |

|---|

Z

低応力試験片加工

| ISAJT-F001 |

|---|

F2

ICP

| JIS H1307、JIS H1352 |

|---|

*1:個々の図面や図面から呼び出される規格の要求による

| 認定の種類 | ISAJT-F005 |

|---|---|

| 認定の対象 | 金属材料 材料試験 |

播磨事業所

■試験コード

■試験項目

| ■主な適用規格 |

|---|

L11

特殊加工(放電など)

| 個々の図面や図面から呼び出される規格の要求による |

|---|

株式会社 神戸製鋼所 チタン本部

■試験

| ■適用規格 |

|---|

高温引張試験

| ASTM E21 |

|---|

常温ラプチャー試験

| ASTM E139、ASTM E292 |

|---|

常温・高温クリープラプチャー試験

| ASTM E139、ASTM E292 |

|---|

- 1947年

- 創業 試験片製作専門工場としてスタート

- 1967年

- 国内初の民間試験場として材料試験受託業務開始

- 1979年

- 兵庫県加古郡播磨町新島に試験場を開設

- 1985年

- 化学・バイオ事業開始

- 1986年

- 機器装置製作事業開始

- 1996年

- ISO 9002 品質システム認証取得

- 1998年

- ISO/IEC 17025 試験所認証取得:機械・物理分野(ISO Guide 25)(JAB)

- 1999年

- ISO/IEC 17025認定(JNLA)

- 2001年

- ISO/IEC 17025認定拡大:高分子材料分野(JNLA)

- 2002年

- ISO 9001:2000 へ移行

医療機器製造業許可取得

- ISO 9001:2000 へ移行

- 2005年

- JIS Q 9100認定取得

- 2006年

- Nadcap(金属材料試験)認定取得

ISO/IEC 17025:2005 への移行及び認定拡大

- Nadcap(金属材料試験)認定取得

- 2007年

- 第一種医療機器製造販売業許可取得

- 2008年

- Nadcap(金属材料試験)認定拡大

ISO/IEC 17025 認定拡大:化学試験分野

- Nadcap(金属材料試験)認定拡大

- 2009年

- GE S-400認定取得

茨城事業所 ISO/IEC 17025 認定取得:機械・物理分野

- GE S-400認定取得

- 2010年

- ISO/IEC 17025認定拡大:EN規格

ISO 9001:2008へ移行

- ISO/IEC 17025認定拡大:EN規格

- 2011年

- ツルイ化学 ISO 9001 認証取得

- 2012年

- GE S-400 認定更新

- 2015年

- ボーイング社からD1-4426認定事業者(MTL)の認定取得

Rolls Royce社の認定取得

- ボーイング社からD1-4426認定事業者(MTL)の認定取得

- 2017年

- Nadcap 非金属材料試験(NMMT)機械試験の認定取得

- 2019年

- Pratt & Whitney社から認定取得

.jpg)