TEST SERVICE

試験サービス

CONTRACT TESTING SERVICE

受託試験サービス

社会の安全・安心を支える、疲労試験やクリープ試験をはじめとする多様な材料試験をご紹介します。

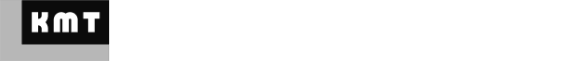

疲労試験

疲労試験とは、材料から採取した試験片にそれぞれの方法(圧縮や引張り、熱、超音波など)で繰返し負荷を加え、また負荷の大きさを変えた試験を複数本実施し、それぞれの破断繰返し数を調べることで、その対象物の“破壊”が引き起こる限界がどの負荷領域なのか(疲労限度)を調べ、疲労限度線図(S-N線図)を取得する試験です。

クリープ試験

クリープ試験とは、電気炉中で加熱された試験片に一定負荷を与えることによってクリープ変形を生じさせ,試験片が破断するまで、温度、ひずみと試験時間を連続計測する試験です。アウトプットとして、破断時間とクリープ曲線などが提供されます。

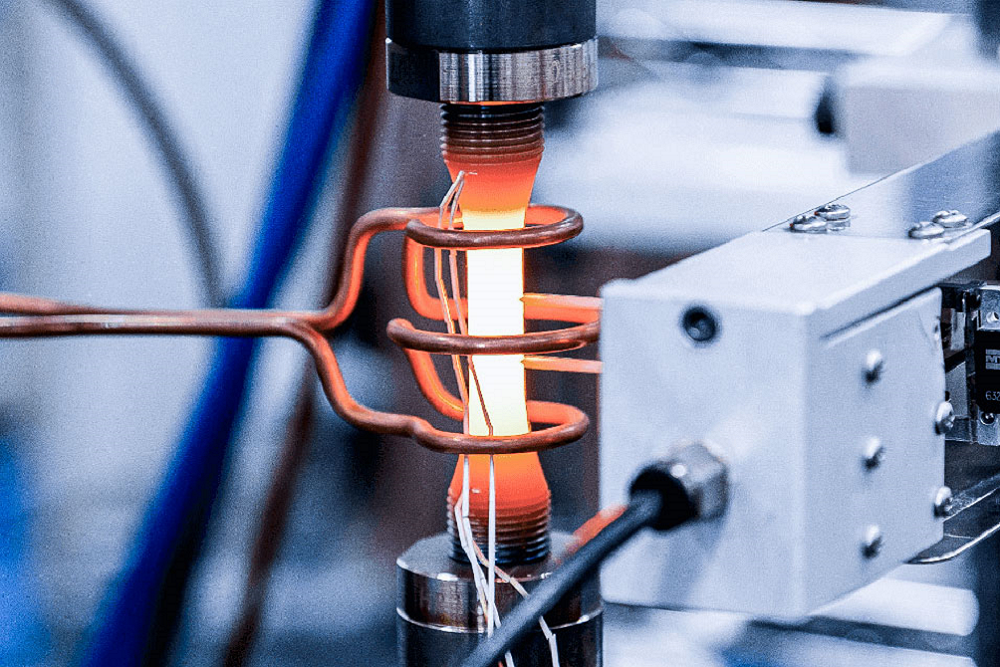

微小(ミニチュア)試験

従来、発電プラント設備の余寿命評価は非破壊的方法、もしくはJIS標準試験片の採取が必要な機械的方法によって行われてきました。昨今、微小(ミニチュア)試験の確立により、定検時のサンプリング採取による設備へのダメージ軽減・工期短縮(低コスト)が実現されています。具体的には直径1mm及び0.5㎜厚のミニチュアサイズの試験片による評価方法や専用試験機の研究開発に取り組み、多くの実績を上げています。

スモールパンチクリープ試験装置

現状の破壊試験は、配管の一部を切り出して直径6mm等の棒状試験片を作製する必要があるため、試験片採取による設備へのダメージが大きくなります。本装置は、設備へのダメージを最小限にするため、配管から小さなサンプリング試料を漉き取り、微小試験片(直径8mm、厚さ0.5mm、円盤型試験片)に加工し余寿命評価を行えるよう開発したものです。

金相試験

金相試験とは、素材の断面や破断面の金属組織や微細析出物を現出・観察する試験になります。 新素材の研究、新加工法の開発および使用劣化部材の健全性の確認に役立てられます。

共振法

共振疲労(英:Resonance Fatigue)試験は、共振の原理を利用し、試験片に繰返しの応力を負荷する試験です。応力振幅に対する破断繰返し数を取得し、S-N線図を作成することができます。

余寿命診断

発電や石油化学等のプラントは予め寿命を決めず充分な安全裕度を持たせた設計を行い製造されています。運転に支障・トラブル(想定外の運転停止や漏洩・火災・爆発等の事故など)が生じないように備え(劣化機器の補修や交換、運転様式の変更など)をしなければなりません。その際の備えを適切なものにするため、後何年安全に運転できるのかを評価するのが余寿命診断・余寿命評価です。

振動試験

振動試験・複合環境試験とは、機械・電気・インフラ設備などの工業製品の機能や性能、信頼性など品質を評価する手段です。繰り返しの振幅を加速度的に対象へ与えることにより振幅による対象へのダメージを再現し、健全性を確認する試験になります。自動車、船舶、人工衛星、航空機、コンピュータ、スマートフォンなど、製品のライフサイクルで機能・性能を失ったり、故障しないように、製品の設計、実験、検査の段階で、使用時の振動や衝撃、高温低温、湿度の環境負荷に耐えられることを、振動試験、複合環境試験によって評価しています。

医療機器評価試験

医療機器の各種試験では、米国材料試験規格(ASTM)および日本産業規格(JIS)に基づく材料や実体の試験を行うとともに、米国食品・医薬品局(FDA) ガイドラインによる引き合いにも対応するなど、国内外の顧客から信頼を得ています。

熱処理

金属材料は熱処理によってその性質が大きく変化します。従って、金属材料の特性を最大限に引き出すためには、熱処理の精度が重要になります。当社では、400℃~1250℃まで制御可能な熱処理炉を有しており、精度の高い溶体化熱処理や焼入れ・焼戻しが行えます。

破面解析・フラクトグラフィー

破面解析(フラクトグラフィ)では、材料の破断面(破面)を観察し、破壊形態を特定することで、破壊に至った『原因』や、破壊が進展した『過程』を遡って推定することができます。

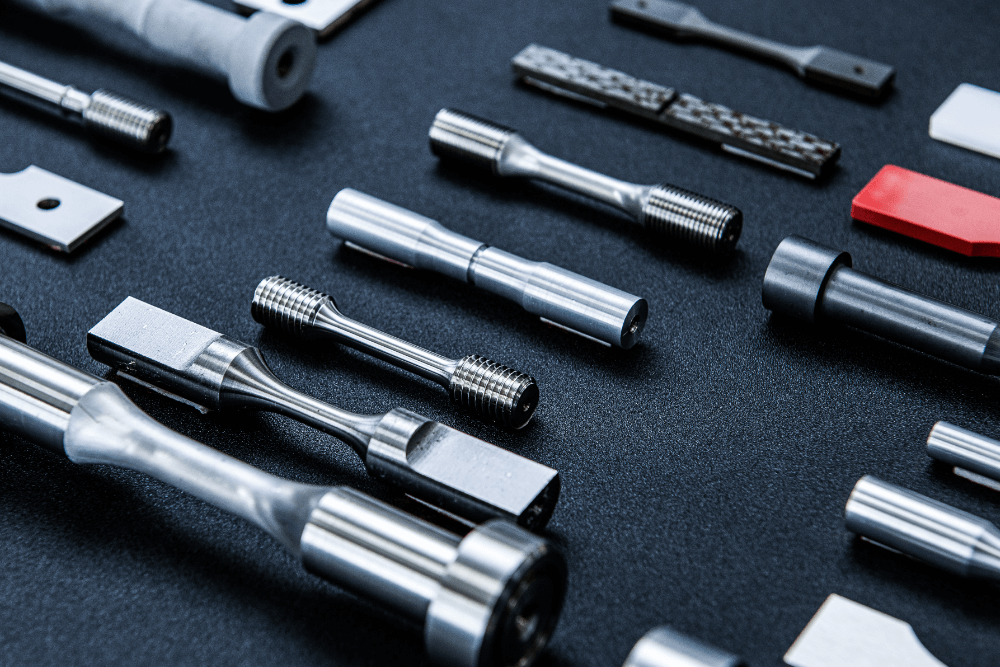

引張試験

引張試験とは、材料から採取した試験片に引張方向の力を加え、破断した時の力や伸びた量などを調べる試験です。この試験によって対象材料が壊れるまでの強さ(強度)やその強さを保てているかを確認します。

ロックウェル硬さ試験

ロックウェル硬さ試験は、硬さ試験の中でも比較的に小さいサイズの試験片または試験体を用いて測定することができ、また硬さ値がそのまま試験機よりダイレクトに表示されることから、短時間で硬さ値を把握することが可能な試験です。

静的強度・破壊靭性試験

破壊靭性とは、材料に生じたき裂または欠陥が、どのくらいの負荷(力)を加えたらき裂が進展していくのかまたは破壊するのかという材料に対する抵抗を示します。その度合いを示す値が破壊靭性値となります。破壊靭性値を評価する試験が破壊靭性試験となります。

腐食試験

腐食試験とは、物質を腐食させる環境因子を抜き出し、腐食を促進させるよう条件下に置くことで耐食性を確認するための試験です。試験は材料または製品から加工した試験片を腐食液(硫酸、硫酸銅、塩化第二鉄など)や環境に所定の温度、時間にて試験し、表面状態の変化や質量変化、腐食速度などを調べることで、その材料が使用環境に耐えられるか否かを調べる試験です。

塩水噴霧試験

塩水噴霧試験は、塩水が付着する環境にて「塩害」を再現した試験になります。大気腐食の主要因のひとつが「塩」であると言われている事から、幅広い工業製品が対象となります。

温度サイクル試験

温度サイクル試験とは、製品の耐久性を確認するために行われる試験の一つで、使用する環境もしくはより過酷な環境を模擬し、高温と低温、さらには湿度を加えて繰り返す試験になります。

樹脂試験

樹脂試験とは、世界中に広く使われているプラスチック材料等が用いられた製品や素材を対象に、ISOやEN規格等に準拠した試験方法にて材料特性を正しく評価することで、品質や安全性を保証するために行う試験です。

シャルピー衝撃試験

シャルピー衝撃試験とは、材料の力学特性測定の1つで、材料に動的な負荷が作用した場合の、エネルギー吸収特性および靭性を測定するものであり、衝撃に対する信頼性評価の一部です。主に材料の品質管理に使用されることが多く、その方法として、振り子型の衝撃試験機を用いることがあります。

SERVICE